Scheduler Improvements

Enersight 2.14 includes several improvements to the scheduling capability focused on reducing the necessity of manual iterative processes associated with Water Recycle workflows and streamlining the input of well list data within the interface.

The following video provides a short demonstration of the scheduling changes in Enersight 2.14.

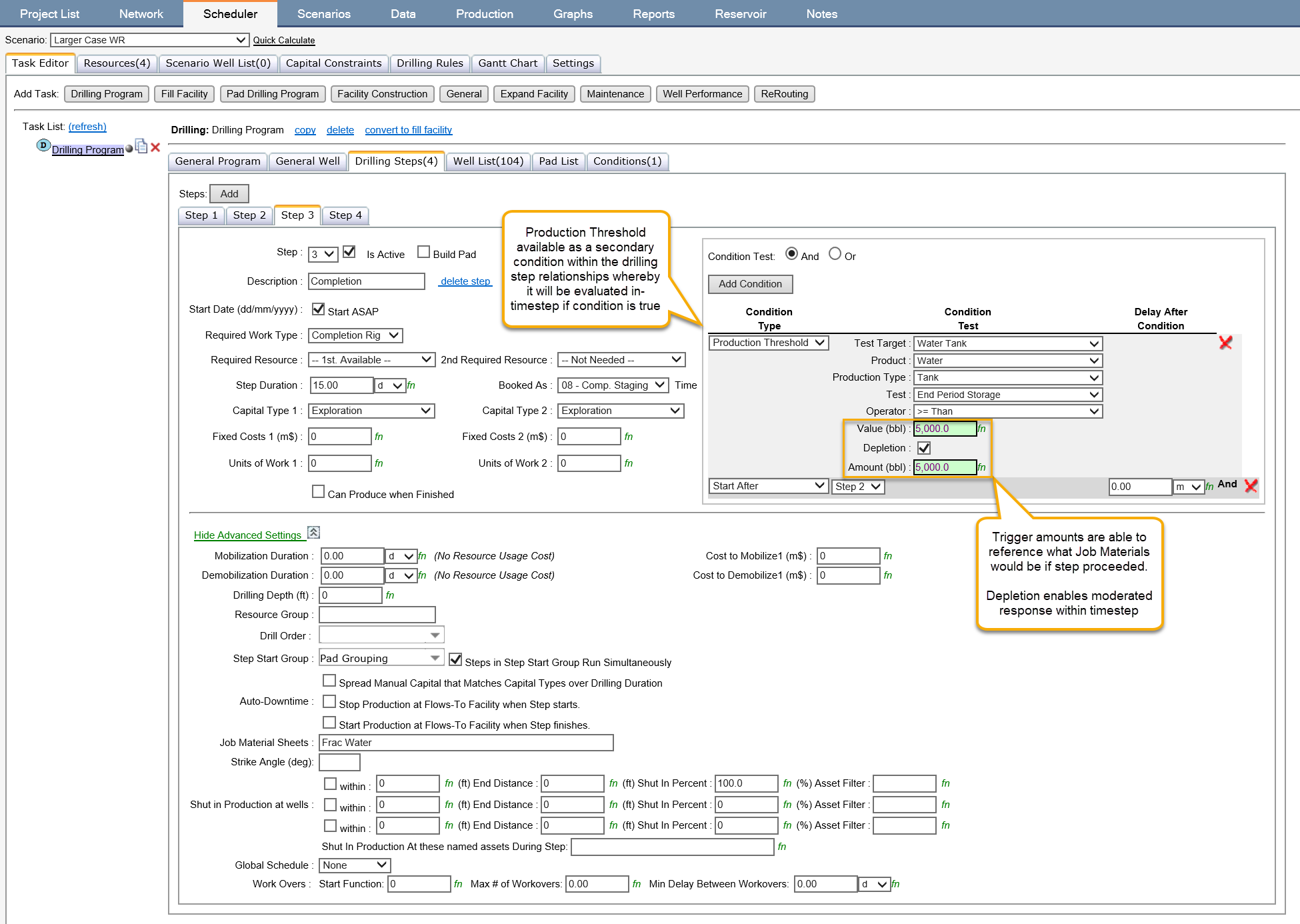

Water Recycle Workflows

Enhanced support for reflecting water management requirements within the simulation is a key feature set within this release, removing the need to iterate through the calculation potentially multiple times to achieve workflows such as:

- Deferring fracking activities where insufficient water is available to proceed

- Increasing the costs associated with fracking where additional water is required to be sourced

- Deferring fracking activities where tank ponds are too full to receive anticipated flow back volumes

- Shutting in production where too much water is being produced relative to available storage

- Deferring on-production of steam injection wells until sufficient available production capacity is available

- Managing the swapout of steam for gas injection within the blowdown case

The resolution of these workflows within a single calculation pass is achieved through improvements in Enersight’s scheduling logic to enable it to dynamically introduce a pause on commencing well activities which may have been pre-scheduled based upon a reference asset’s production or tank storage levels within the current simulation. Specifically, the relationship of Production Threshold Condition has been expanded from being a task level condition to a step level activity, expanded to support tanks not just throughput constraint-based rules and then had extra Test Target options added to enable this to be evaluated against the wells ‘Flows To’ or against an asset matching a User Data field’s input string as specified. To ensure that this condition creates a meaningful and moderated response rather than just returning true or false for all activities, a new Depletion input has also been introduced whereby each successive action by the scheduler accumulates this amount against the original trigger. To assist in ensuring that the right information is available to trigger the required pauses, Job Material results are now also available mid-simulation using the function of @JobMaterialsResults([Asset], Material Type Name, Type, [Index]), whilst the amount of Job Materials created by a successful step can be pre-evaluated using the function of @TaskConditionJobMaterials(Job Material Index Number).

Click image to expand or minimize.

See How to Set up a Dynamic Water Recycle Calculation for configuring your model to include these features.

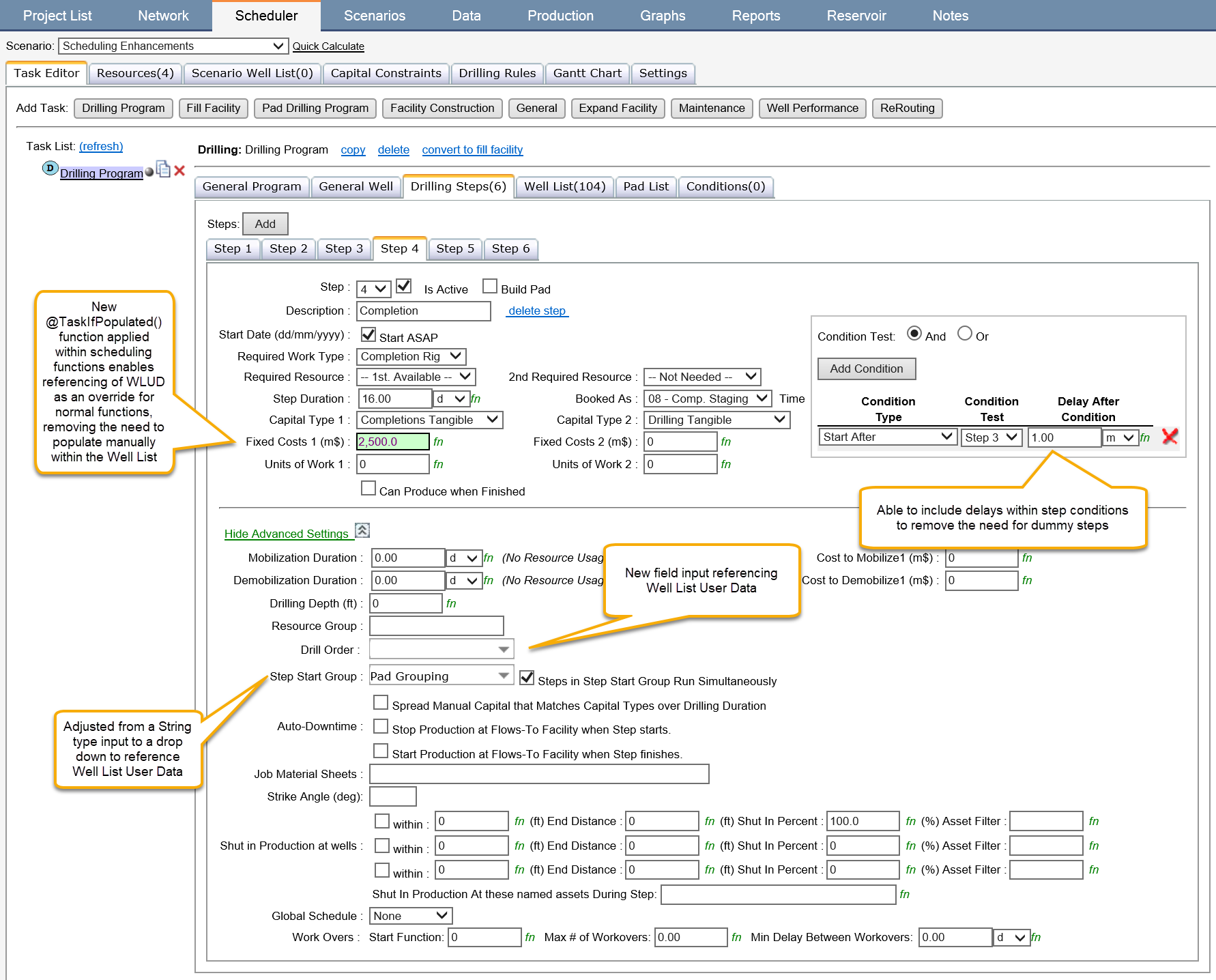

Schedule Data Management

The Well List data input requirements of Enersight 2.14 have also been significantly reduced along with their associated QA/QC burden via streamlining the data inputs required by expanding the drilling program step definitions and their step conditions, potentially removing many columns in this list and extraneous delay steps. Specifically, within the Advanced Settings now have the ability to reference the Well List User Data to populate Drill Order and Step Group relationships as well as having a new function of @TaskIfPopulated(User Data Definition Name, Alternative) that enables overrides to the unit cost and duration logic if the reference field is populated. Finally, the Drilling Step Conditions of Start After and Start Start now have the capability to add delays intrinsically rather than having to create dummy steps to create the required gaps between activities.

Click image to expand or minimize.

See How to Simplify your Drilling Program and Well List on how to configure your model to include these features.

Other Scheduling Enhancements

- Added ability to turn OFI on and off for a drilling program for all relevant steps within a single click at the Drilling Program level as well as enact a bulk edit across all drilling programs. This removes the need to go into each relevant drilling step and uncheck each halo in order to undertake differential cases to measure the impact of this interference.

- Enabled Static and Producing wells to have their Flows To changed when being ‘drilled’ with a wellcount of -1. This facilitates the bulk import of re-route tasks or avoids having to introduce non-desirable abstract networks to model re-directions of flow at the well level.

- Enhanced the Fill Facility scheduling evaluation capability to cover constraints of BOE and CO2 products types and the associated workflows (e.g. injection limitations).

- Added Water Cut as a Wait For Scheduling type condition

- Made the ‘Not Booked’ Activity Type category read only if not already customized so as to streamline future configurations with Execute given the special duplicate exclusion logic assigned against this type. If it is customized and utilized within the scenario then a warning has been added identifying that it may be problematic for integrations.